If you are curious about knowing what are the likely causes of steam turbine vibrations in a thermal power plant, then this article is for you.

Let’s get started…!

Steam Turbine in Thermal Power Plants

When we scrutinize the proportion of electricity generation through conventional and non-conventional energy resources, we observe that more than 50% of the world’s electrical energy requirement is getting fulfilled by nuclear and thermal power plants. One of the most fundamental components that can be referred to as the heart of these power plants is a steam turbine.

The steam by the boiling of water (sometimes with the addition of some solvent) with the help of heat drives the rotors of a turbine, eventually causing the coupled shaft to rotate. The shaft is further connected to a generator that converts this rotational motion into electricity.

Vibrations in a Steam Turbine

Structurally a steam turbine is a complex assembly compounding many delicate components—any sort of uncontrolled vibration due to a component can cause system failure and, consequently, a significant disaster.

One of the recent examples of such incidents is a blast in the turbine generator unit of 500MW in the Anpara D thermal power plant in UP India, which happened in 2019.

Thus, the analysis of vibrations’ cause and intensity is essential to ensure proper operations and safety.

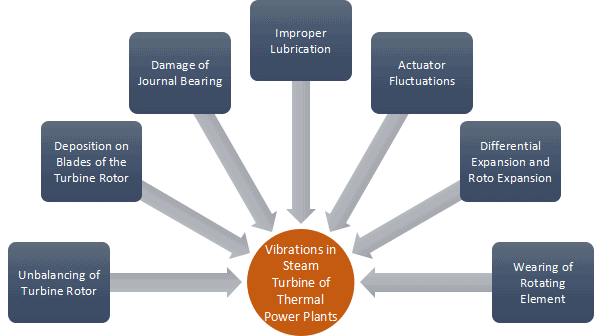

Major Causes of Vibrations in a Steam Turbine

Here we will discuss the likely major causes of vibrations in a steam turbine of any thermal power plant:

1. Unbalancing of Steam Turbine Rotor

There are many possible reasons for the unbalancing of a turbine rotor. One of them could be the uneven mounting, misalignment, or structural inaccuracy.

Another reason for an unbalanced rotor that can be a likely cause of vibrations in a steam turbine is the formation of local heating spots by friction.

When the turbine’s rotor touches/strikes the stator, a local heating spot is generated and causes deformation in the shaft. If left unsolved, it can cause severe damage.

2. Wearing of Rotating Element

In an operational steam turbine, the rotating components are under the influence of constant static and dynamic loading scenarios.

This continuous loading and high pressure can cause wear, imbalance, and dislocation of the rotating elements that result in unnecessary vibrations.

Another reason for wearing parts can be the sudden impact of steam on the turbine rotor. This impact happens in the case of immediate and unprepared tripping of the steam turbine.

The wearing of components may cause little amplitude of vibrations at first but not an immediate failure action. However, if not amended for a long time, it would make the situation worse.

3. Deposition on Blades of the Steam Turbine Rotor

There exist several factors that can affect the formation of deposits on turbine rotor blades and other components.

These adherent deposits are responsible for the deformation of turbine blades, consequently making the blade surface rough and uneven. This phenomenon increases the resistance for steam to flow and creates undesirable vibrations.

It is essential to know that the deposits can accumulate by utilizing contaminated and impure water to generate steam. A 30MW steam turbine can lose up to 5% of its generating capacity in a fouled condition.

4. Damage of Journal Bearing

There are different wear, fatigue, or crushing mechanisms during service conditions, which can damage one of the most sensitive parts of a steam turbine – journal bearing.

This damage will be responsible for the rotor shaft instability and induce uncontrolled and high amplitude vibrations.

Failure of a journal bearing results in the complete shutdown of the turbine, which means a heavy loss in regards to power generation.

The situation can be avoided by having timely investigations of crack formation in the bearing elements and treating them in its initial stage.

5. Differential Expansion and Roto Expansion

Technically, the Differential Expansion is termed as the relative measurement of the rotor’s axial thermal growth with respect to the case.

On the other hand, the Rotor Expansion is the absolute measurement of the rotor’s axial thermal growth with respect to the turbine’s foundation.

These phenomena happen due to uneven thermal expansions when the turbine is in the heating zone, causing vibrations in a thermal power plant’s steam turbine.

6. Actuator Fluctuations

In order to maintain a steady rotation of a turbine shaft to generate constant electricity, an actuator and the governing system are used.

But sometimes, due to some operational issues, the steam input is not according to the load requirements. It causes sudden jerks and, eventually, vibrations in the turbine, which are necessary to avoid.

7. Improper Lubrication

A turbine consists of multiple rotating parts. Proper circulation of lubrication oil among the turbine components ensures permissible operations.

Deficiency or lack of lube oil can cause friction in the components that will lead to un-avoided vibrations and severe damage.

It is crucial to note that the International Association of Engineering Insurers report that the highest frequency of steam turbine failures in the world is because of the loss of oil.

Conclusion

Vibrations are the to and fro periodic motion of an element about a fixed point. Normal vibrations are acceptable in any component that is under the action of any continuous impact.

But when these vibrations start to grow and reach the undesirable level, they cause permanent failure and, consequently, significant damage to the system.

In the steam turbine of a thermal power plant, multiple factors can be responsible for creating unnecessary vibrations. They can be caused by insufficient lubrication, wearing of any component, or pathetic service conditions.

It is a matter of high significance to diagnose such vibrations and treat them as quickly as possible. Any carelessness in this regard can lead to severe impacts and damages.

Hope you found this guide useful. Kindly subscribe to our e-mail newsletter and also share it with your friends and industry colleagues on Facebook, Twitter, and LinkedIn!

How has your experience been so far on this subject? Kindly share your thoughts in the comments!

PS – for any type of Operations & Maintenance requirement in your thermal power plants, please do get in touch with us. We are a team of experienced engineers who are the doyens in this field for the last two decades. We would be happy to add value to your process.

References

- https://maintenancepartners.com/en/steam-turbine-rotating-imbalance-root-cause-identified-and-solved-within-5-days/

- Fatigue damage and failure of steam turbine rotors by torsional vibrations byA. P. Bovsunovskii,aO. Yu. Chernousenko,bE. V. Shtefan,cUDC 620.178; 534.1 and D. A. Bashtac 2010

- https://www.suezwatertechnologies.com/handbook/chapter-18-steam-turbine-deposition-erosion-and-corrosion#:~:text=Adherent%20deposits%20form%20in%20the,to%20the%20flow%20of%20steam.&text=Uneven%20deposition%20can%20unbalance%20the%20turbine%20rotor%2C%20causing%20vibration%20problems.

- An investigation into failure analysis of interfering part of a steam turbine journal bearing byM.Mehdizadeh and F.Khodabakhshi

- https://www.stiweb.com/kb_results.asp?ID=141#:~:text=Differential%20Expansion%20on%20a%20turbine,respect%20to%20the%20turbine’s%20foundation.

- http://www.powerservicesgroup.com/2012/03/lots-of-lube-oil-emergency-lube-oil-systems/#:~:text=The%20International%20Association%20of%20Engineering,due%20to%20loss%20of%20oil.

What are the measures for human (working there) safety ?