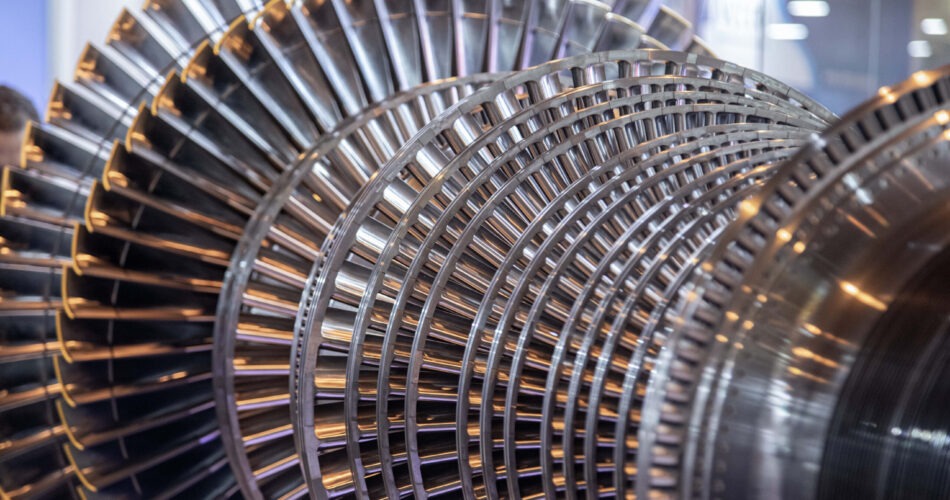

This article entails the significance of diagnosing and troubleshooting the causes of vibrations in a steam turbine of a thermal power plant.

It contains different historical case study references and industrial experiences and techniques to deal with such problems.

Let’s get into it.

Why is it important to troubleshoot the vibrational cause of a steam turbine?

Here we will illustrate the seriousness and importance of the need to troubleshoot any vibrational cause that can come about in a steam turbine of any thermal power plant.

The rotor of a 225MW steam turbine plant being used for above 17years, in Tennessee Valley Authority Gallatin Unit 2, broke down because of the vibrational causes on June 19, 1974.

The consequences of this incident were massive destruction and shutting down plants. Other than that, we have a case study in which:

An Indian steam turbine generator plant generating 300MW of energy got tripped due to some mechanical failure involving blade loss, on March 31, 2012.

The plant was equipped with a proper protection system and monitoring and diagnostic tools, which helped the plant trip and prevented a major disaster.

Major vibrational causes in a steam turbine and their Troubleshooting

Since we have become aware of the severity of any vibrational cause in a steam turbine that can be the source of a severe disaster in the thermal power plant, we should now look at the troubleshooting methods of vibrations.

Remember, while doing that, we will be diagnosing the causes by comparing the frequencies of vibrational spectrums coming out of the affected or vibrating component.

1. Unbalancing

To be precise, the unbalance is a typical process that occurs in all rotating components, which is not a problem to some extent. But if increased to a higher degree, it can create serious consequences.

Unbalancing of the rotor can be treated by eradicating the factor that is causing it.

- If there is an improper mass distribution, adding the required amount of weight on the affected side would help reduce and ultimately eradicate the extra vibrations.

- In the case of a rotor bow, replacing the rotor could be the best option.

2. Misalignment

Another critical factor that can cause variation in the vibrational behavior of a multi-bearing shaft line of the steam turbine is the immoderate misalignment, which exerts an excessive amount of bending moment at the couplings.

One of the indications for the misalignment occurrence is the revamping in hot and cold vibrational behavior. This impact can be observed as once-per-revolution vibration.

In an ideal situation, the complete turbine-generator unit shaft line having an overall length with the approximation of 70m should be a continuous and smooth curve. Even a slight deviation from such ambiance can be cited as misalignment.

The figure below is representing the shaft line misalignment in the turbine-generator system. It is responsible for a change in the vibrational behavior of the steam turbine.

To avoid such conditions or treat misalignment issue:

- We should ensure sufficient clearance between stationary and rotating parts as well as the concentricity between the shaft and the bearing.

- Since the situation occurs mainly due to the faulty bearings, replacement of bearings would help eliminate unwanted vibrations.

3. Rotor Bow

We need to understand three different types of turbine rotor bow.

- The first one is the ‘Elastic bow,’ which occurs due to static load on a rotor.

- The second one is ‘Temporary bow.’ There are mainly two reasons for the temporary rotor bow to occur: uneven temperature field in a rotor and anisotropic properties of the rotor material.

- In the last, we have the ‘Permanent rotor bow.’ The reason for the generation of permanent rotor bow is plastic deformation. This is the most severe one as the center of gravity shifts from the centerline.

According to the recent investigations, the rotor bowing happens in rotors manufactured more than ten years ago.

Rotor bow can be treated by bow straightening techniques. There are vertical and horizontal methods for the treatment of respective types of rotor bow, and different industries and turbine consultants provide these services.

4. Bearing Problems

As per some studies, a comparatively sizeable relative displacement can occur under cyclic loading scenarios, which can eventually become a reason for bearing part loosening and inadequate clearance.

This situation can reduce the turbine journal bearing’s service life due to the fatigue mechanism’s failure.

One of the problems specific to shaft journal bearings is the oil film instability, which is the reason for the induction of self-excited vibrations in a thermal power plant’s steam turbine.

The problem arises from the vertical displacement of bearing, resulting from either thermal deformation or foundational distortion.

Since the bearing issue can lead to the instant shutdown of plants and can cause both machinery and economic losses, changing bearings in such a situation gives the best solution for troubleshooting unnecessary vibrations in a steam turbine of a thermal power plant.

5. Rotor Crack

Another serious phenomenon as a mechanism of failure in rotating systems, especially steam turbines, is the high cycle fatigue. Incomplete information on its significant parameters could lead to catastrophic failure of the rotor.

In high cycle fatigue, one of the most influential factors in crack growth is high temperature.

In most of the rotating systems, mainly including steam turbines, the process of generating high cyclic fatigue is prevalent, and it should be avoided to prevent any significant loss.

One of the reasons that can lead to severe failure is insufficient useful and necessary information regarding important rotor parameters.

In general, shaft stiffness gets reduced due to cracks which in turn causes resonance to shift to a lower rotational speed.

If the rotor had been in operation for more than ten years, replacement would be the best choice. Otherwise, repairing it would be less time-and-cost consuming.

Without a doubt, joining and repairing two parts of a turbine requires considerable expertise. It also includes computer efficiencies in 3D Modelling and Finite Element Analysis (FEA) to ensure its feasibility.

Conclusion

Troubleshooting of vibrational causes in the steam turbine of a thermal power plant helps reduce the chances of any catastrophic failure.

We always need to deem the significant reasons that can be a leading source of turbine failure. Historical incidents and research can help us to identify them.

Moreover, proper monitoring and diagnosing systems should be installed in a thermal power plant’s turbine-generator system to detect any fault at an earlier stage.

An imbalance rotor, misaligned shaft or rotor, crack in the rotor blade, rotor bow, and bearing failure are the major trouble-causing issues.

Troubleshooting these major vibrational causes can improve any steam turbine-generator system’s service life in a thermal power plant.

Hope you found this guide useful. Kindly subscribe to our e-mail newsletter and also share it with your friends and industry colleagues on Facebook, Twitter, and LinkedIn!

How has your experience been so far on this subject? Kindly share your thoughts in the comments!

PS – for any type of Operations & Maintenance requirement in your thermal power plants, please do get in touch with us. We are a team of experienced engineers who are the doyens in this field for the last two decades. We would be happy to add value to your process.

References

file:///C:/Users/NCD/Downloads/YamunaCaseStudyPHMB.pdf

http://mda139.net/steamturbine/rotor-alignment.html

Investigation of Bowing of Steam Turbine Rotor during Long Term Service By Seishin KIRIHARA,Masao SHIGA, Mitsuo KURIYAMA, Ryoichi SASAKI and Katsukuni HISANO

An investigation into failure analysis of interfering part of a steam turbine journal bearing M. Mehdizadeh, F. Khodabakhshi.